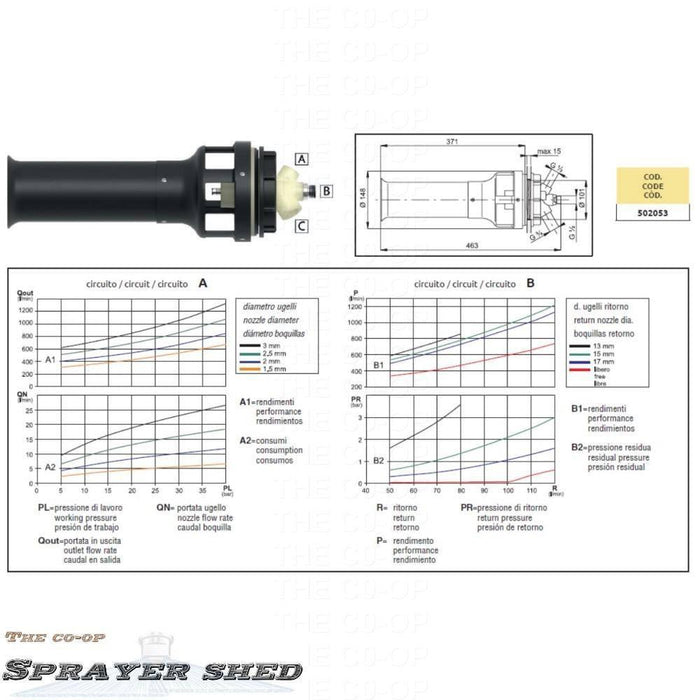

"SUPERMIX" hydraulic agitator

The SUPERMIX agitator body contains three circuits:

A Pressure

B Return

C Product injection, additional pump or air mixing

Circuit A: PRESSURE

By using the working pressure, the mixing power of SUPERMIX is greater than the performance of traditional systems, ensuring a flow rate of 300 to 1300 l/min. depending on the pump and nozzle used. Graph A2 illustrates consumption, while graph A1 shows the corresponding performance values using nozzles with diameter 1.5 - 2 - 2.5 - 3 mm.

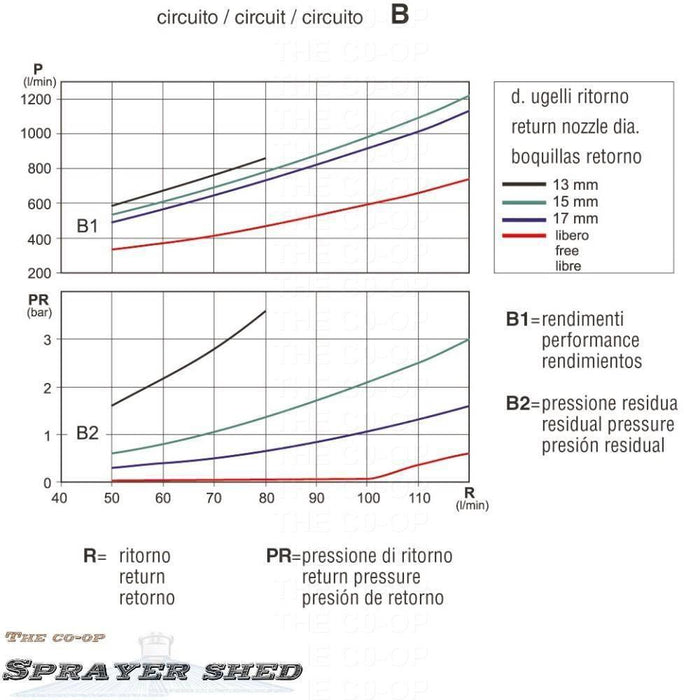

Circuit B: RETURN

This circuit utilises the pump return flow during limit, control and tank filling operations, when all the pump delivery fluid passes through the circuit. Recommended for low-pressure treatments, average and low volumes, pneumatic systems and spraying.

Graph B2 illustrates the residual pressure in the circuit at various flow rates, while graph B1 shows the corresponding performance values without a nozzle and using nozzles with diameter 13 - 15 - 17 mm.

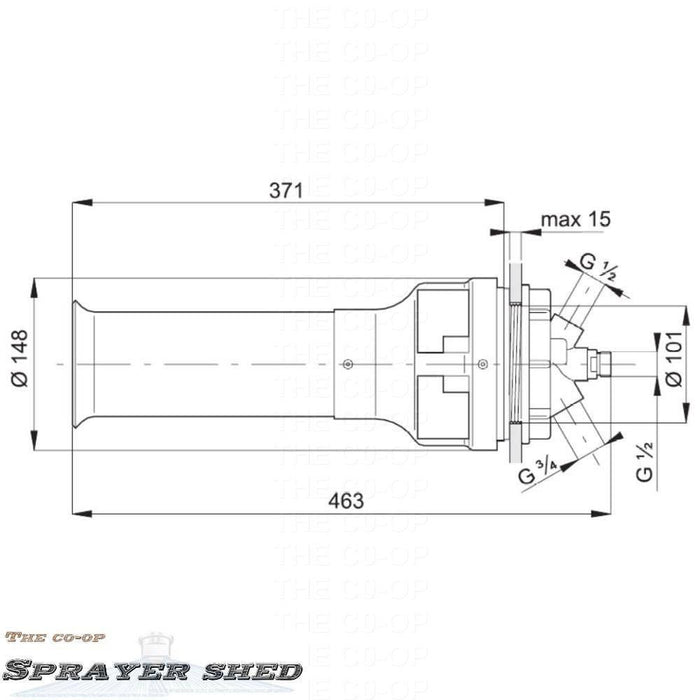

- Can be adapted to various tank shapes

- Double Venturi circuit to increase efficiency and reduce water consumption

- Threaded G connector for simple installation on tank

- Suitable for low pressure (nozzles 5-7-9- mm) or high pressure (nozzles 2-3 mm) operation

- Polypropylene body